VACFILLER is a range of machines designed, made, and commercialized by Deremaux Sarl for the reliable filling of glass or plastic ampoules and for obtaining the best productivity from a packaging chain.

Automated, semi-automated, or manual, these fillers ensure reliable, high quality production with the performance, productivity, and profitability levels our customers demand.

Their simplicity of use, their studied ergonomics, and their throughput speed guarantee high quality production while limiting unproductive time.

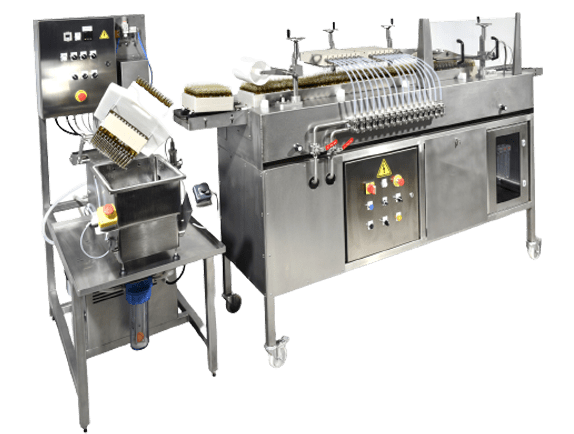

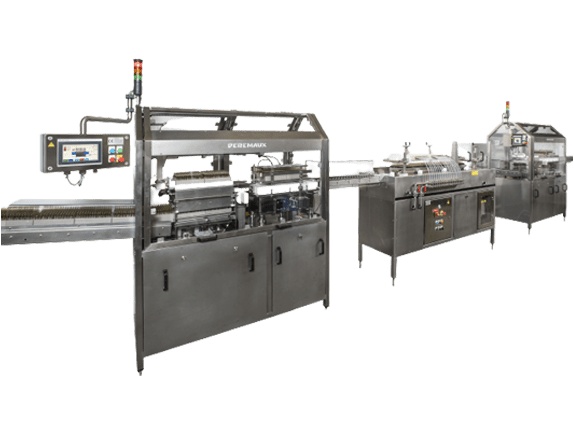

They fit perfectly into a complete production line for the packaging of liquids in ampoules.

Customizable filling line

With four filler models and a wide range of complementary modules, each production line is precisely matched to the customer’s specific needs.

Small footprint

Ergonomic and compact, the VACFILLER machines can be easily integrated into all types of laboratory.

Compliant with BPF and FDA specifications

The whole of the VACFILLER range complies with BPF (French good practice in manufacturing) and FDA requirements for pharmaceutical industry products and dietary complements.

Four models of ampoule filler to meet every requirement !

The VACFILLER range of liquid fillers comes in four models to ensure each requirement is met in terms of volume and throughput speed.

VACFILLER 10

Manual bench-top machine

Placed on a lab bench for filling very small batches of ampoules.

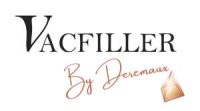

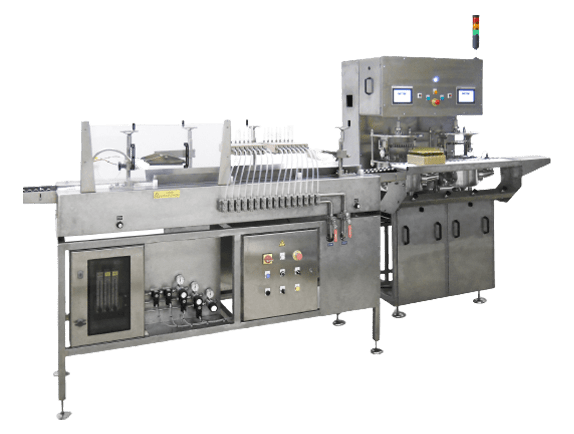

VACFILLER 200

Semi-automatic machine

For filling typical industrial volumes of ampoules.

A bespoke, upgradable production line with many advantages...

The VACFILLER range can package ampoules from A to Z in record times. There are many advantages in all of the machines, not the least of which is a quick return on investment.

VACFILLER machines fill ampoules with extreme accuracy, guaranteeing reliability and quality.

Ergonomic and intuitive, VACFILLER machines have a short learning curve thanks to their simplicity of use.

VACFILLER modules are standard design machines. Maintenance is therefore performed using commonly available parts.

By filling their ampoules in-house, laboratories maintain full control over the packaging chain, especially on quality and lead-time.

Each model meets a well-defined requirement, ensuring perfect productivity, and accordingly a very short payback time.

Excellence in the filling of fine-tipped ampoules in the laboratory !

VACFILLER ampoule fillers are designed to fulfil the requirements of laboratories performing analysis, calibration, or sampling.

- Pharmaceuticals

- Agri-food

- Chemicals

- Cosmetics

VACFILLER machines package liquids in ampoules made of glass or plastic, such as double-tipped ampoules, ampoule bottles, and Flackpull membrane ampoules.

Double-tipped ampoules

Flackpull membrane ampoules