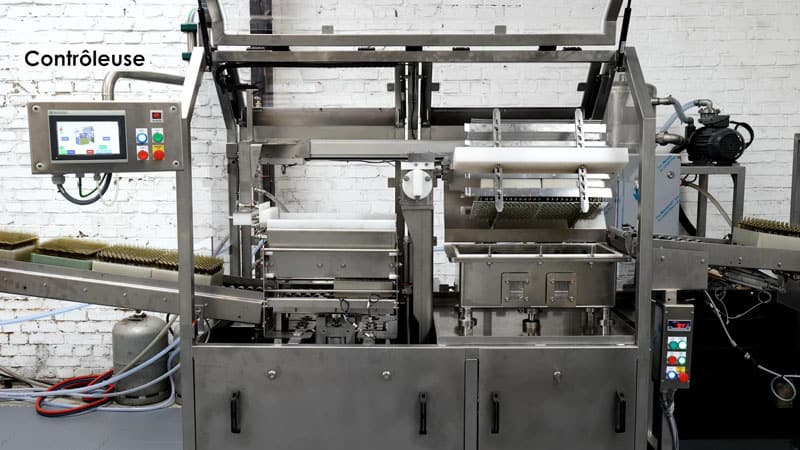

Once the tips are sealed, it is essential to make sure the ampoule is free of leaks

The Inspection module is one of modules in the basic set recommended for every production line.

It can also be chosen as a complementary module for use with VACFILLER models 100, 200, and 300.

It fits perfectly into a fine-tip ampoule filling line.

Capacity

Up to 300 crystallizing dishes per hour (measured on mains water)

Customizable filling line

With four filler models and a wide range of complementary modules, each production line is precisely matched to the customer’s specific needs.

Small footprint

Ergonomic and compact, VACFILLER machines can easily be integrated into all types of laboratory.

Compliant with BPF and FDA specifications

The whole of the VACFILLER range complies with BPF (French good practice in manufacturing) and FDA requirements for pharmaceutical industry products and dietary complements.

What is the purpose of the inspection module?

The Inspection module automatically verifies the ampoules for leak-tightnessafter sealing.

It is easily installed between the Sealer and Washer on an ampoule filling line.

How does it work ?

With a standard construction based on Vacfiller 300, this machine loads two crystallizer dishes into the inspection tank.

The inspection operation then takes place by subjecting the ampoules to a vacuum.

Ampoules with bad seals end up partly emptied.

Designed to guarantee the leak-tightness of fine-tip ampoules !

With its simplicity of use and studied ergonomics, the Inspection module guarantees the airtight closure of fine-tip ampoules.

- Automatic machine matched to the throughput speed of the filler ;

- Standard stainless steel design based on the Vacfiller 300 ;

- All parts in contact with the product are FDA certified ;

- Easy access and easy to clean ;

- Fast changeover of format ;

- Easily removable stainless tank with aseptic valves for direct access. All the connections are clamped ;

- Modifiable control programs configurable from user interface ;

- Vacuum and cycle timer settings can be modified and saved for optimum control ;

- Addition/modification of recipe programs for various products ;

- Assisted troubleshooting from the user interface ;

- Recording and repeatability of different settings ;

- Bypass operating mode possible.

Installation prerequisites

- 220V 50Hz power supply ;

- Filtered compressed air at a constant 6 bar ;

- Vacuum ;

- Effluent discharge connection.

Optional extras

- Development of custom programs for your specific products ;

- Liquid ring vacuum pump with partial water recycling ;

- Liquid ring vacuum pump with total water recycling + chiller unit for almost zero water consumption ;

- Inspection by contrast using revelator fluid ;

- Free choice of automation brand.

A bespoke, upgradable production line with many advantages

The VACFILLER range can package ampoules from A to Z in record times. There are many advantages in all of the machines, not the least of which is a quick return on investment.

VACFILLER machines fill ampoules with extreme accuracy, guaranteeing reliability and quality.

Ergonomic and intuitive, VACFILLER machines have a short learning curve thanks to their simplicity of use.

VACFILLER modules are standard design machines. Maintenance is therefore performed using commonly available parts.

By filling their ampoules in-house, laboratories maintain full control over the packaging chain, especially on quality and lead-time.

Each model meets a well-defined requirement, ensuring perfect productivity, and accordingly a very short payback time.