The VACFILLER 200 is designed for the semi-automatic filling of ampoules, in typical industrial volumes.

Its filling cycle and overturning system are both automatic. Its features ensure production quality and regularity to match the performance, productivity, and profitability goals of our customers.

Its simplicity of use, its studied ergonomics, and its throughput speed guarantee high quality production while limiting unproductive time.

To best fulfil the needs of each client, the VACFILLER 200 ampoule filler comes in two versions: single or dual station.

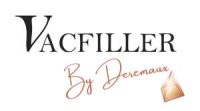

With a standard stainless steel design, the VACFILLER 200 consists of 3 basic modules (filler + sealer + inspection module). It fits perfectly into a complete ampoule packaging line.

VACFILLER 200.1 > single station, capacity

up to 150 crystallizing dishes per hour (measured on mains water)

VACFILLER 200.2 > dual station, capacity

up to 220 crystallizing dishes per hour (measured on mains water)

Customizable filling line

The VACFILLER 200’s three basic modules can be complemented with optional devices to build a filling line that matches the customer’s requirements.

Small footprint

Ergonomic and compact, the VACFILLER 200 machine can be easily integrated into all types of laboratory.

Compliant with BPF and FDA specifications

The whole of the VACFILLER range complies with BPF (French good practice in manufacturing) and FDA requirements for pharmaceutical industry products and dietary complements.

A bespoke, upgradable, semi-automatic ampoule filling line !

The VACFILLER 200 consists of 3 basic machines for quick, semi-automatic filling. Along with the complementary modules, it can package ampoules from A to Z in record time.

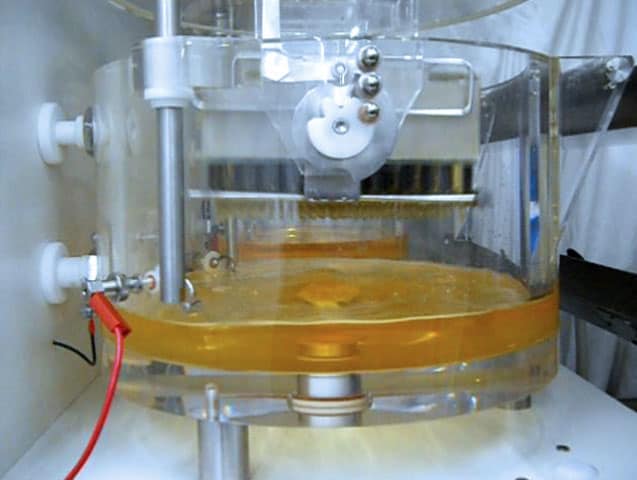

Filler

The VACFILLER 200 filling machine performs fast-throughput automatic filling with extreme accuracy. Ampoules can be loaded by gravity or from a motorized conveyor.

Seals all types of fine-tipped ampoule. With a variable speed motorized conveyor and adjustable settings, it adapts to all throughput speeds and ampoule formats.

Automatically inspects the ampoules after sealing for leak-tightness.

Complementary modules can be integrated with the production line right from the outset or retrofitted as and when requirements change.

VACFILLER 200 - A semi-automatic fine-tipped ampoule filler with many advantages

Like the rest of the VACFILLER range, the VACFILLER 200 automatic filler offers users a whole range of benefits. Perfect control of the process and the consequent productivity gains mean a good return on investment.

The VACFILLER 200 machine fills ampoules with extreme accuracy, guaranteeing reliability and quality.

Ergonomic and intuitive, the VACFILLER 200 machine has a short learning curve thanks to its simplicity of use.

VACFILLER modules are standard design machines. Maintenance is therefore performed using commonly available parts.

By filling their ampoules in-house, laboratories maintain full control over the packaging chain, especially on quality and lead-time.

The VACFILLER 200 meets a well-defined requirement, ensuring perfect productivity, and accordingly a very short payback time.

Designed to fill ampoules quickly, reliably, and with a minimum of fuss !

With its simplicity of use and studied ergonomics, the VACFILLER 200 line fills ampoules reliably and quickly to guarantee excellent productivity. The VACFILLER 200 single station can fill up to 20,000 x 10ml ampoules per running hour. The VACFILLER 200 dual station can fill up to 35,000 x 10ml ampoules per running hour.

Ampoule fillers

- Quick easy adjustment thanks to the index markings ;

- Manual loading and unloading ;

- Automatic overturning ;

- Crystallizing dishes processed one at a time ;

- Fast changeover of format -> short preparation times ;

- Automatically controlled filling cycle ;

- Rapid dismantling of vat tubes and accessories for cleaning ;

- Automatic cleaning assistance cycle ;

- Stainless-steel tank with quick removal for servicing, aseptic valves, clamped connections ;

- Adaptable filling and cleaning programs configurable from the user interface ;

- Modification and recording of cycle settings to optimize filling with oily, foaming, or other substances ;

- Addition/modification of recipe programs for various products ;

- Assisted troubleshooting from the user interface ;

- Liquid ring vacuum pump with non-recirculating water.

Sealer

- Closure by heat-sealing on the fly ;

- Variable speed motorized conveyor ;

- Flame lighting and extinguishing cycle controlled by PLC ;

- Flame detection to guarantee operator safety ;

- Horizontal safety screen made of “Securit” glass.

Installation prerequisites

- 220V 50Hz power supply ;

- Filtered compressed air at a constant 6 bar ;

- Compressed air, propane, and oxygen ;

- Cold water/hot water ;

- Vacuum ;

- Effluent discharge connection.

Optional extras

- Development of custom programs for your specific products ;

- Filling in nitrogen atmosphere and nitrogen buffer tank ;

- Free choice of automation brand ;

- Liquid ring vacuum pump with partial water recirculation ;

- Liquid ring vacuum pump with full water recirculation + chiller unit for almost zero water consumption.

VACFILLER 200 : Excellence in the automatic filling of ampoules in the laboratory !

The VACFILLER 200 ampoule filler is designed to fulfil the requirements of laboratories performing analysis, calibration, or sampling in typical industrial volumes.

- Pharmaceuticals

- Agri-food

- Chemicals

- Cosmetics

The VACFILLER 200 machine packages liquids in ampoules made of glass or plastic such as double-tipped ampoules, ampoule bottles, or Flackpull membrane ampoules.

Double-tipped ampoules

Flackpull membrane ampoules